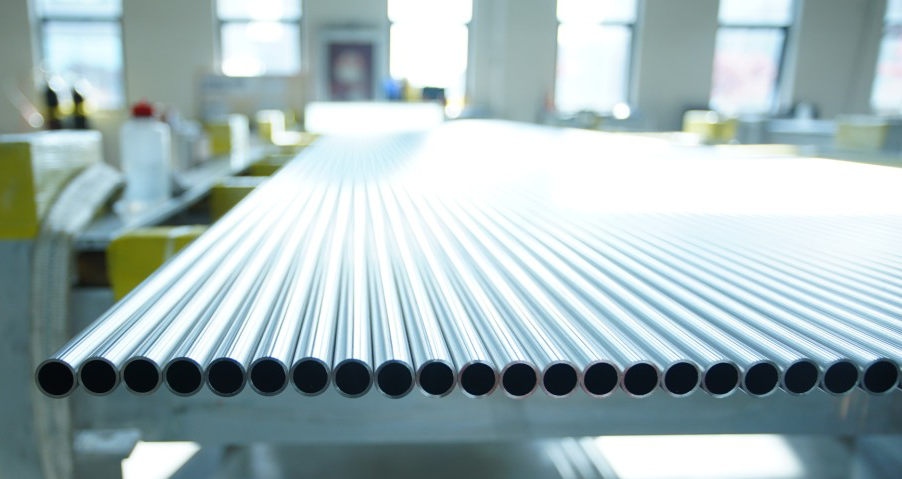

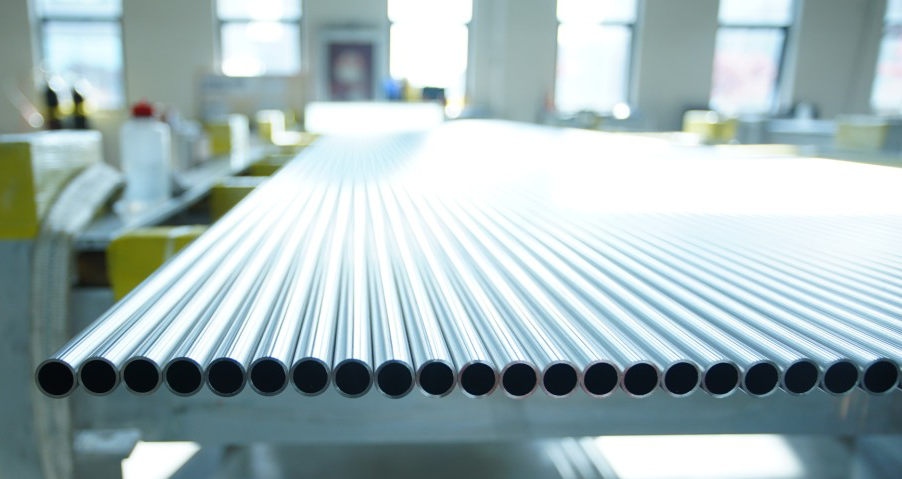

Light tube applications are very wide, such as electronic semiconductors, pharmaceuticals, chemicals, locomotives, aerospace, laboratories and other fluids, instrumentation, hydraulics, machinery and other pipeline systems.

General specifications: 1/8"-2" ,

Wall thickness: 0.5 -7.0 mm.

Fixed length: 4 meters or 6 meters, if there are other needs, can be discussed.

Materials: TP304/304L,TP316/316L ,S31603, SUS316L

Smelting processes:AOD,VOD,AOD+ESR,EF+VOD/AOD+VAR,EF+VOD/AOD, VIM+VAR

Delivery status: BA, BA-Polishing.

Implementation standards: ASTM A269/632, JIS G3459, and customer requirements.

Main tests: chemical composition, electrometric properties, roughness testing, appearance inspection, dimensional inspection,Eddy current test (100%), PMI material identification (100%).

Features:

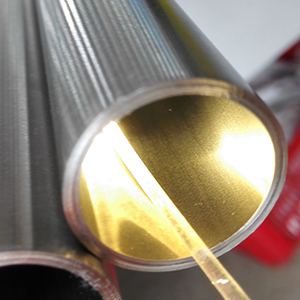

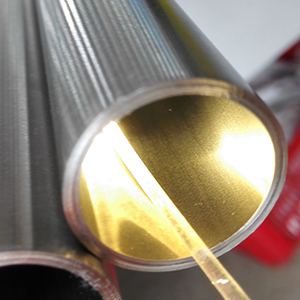

Low roughness of the inner wall, controllable range ofRa10 to Ra15 μin;Ultra-pure stainless steel materials to meet electrolyte requirements;

Oil drawing can improve the quality of inner wall , steel tube can be directly processed by electrolytic polishing without any mechanical polishing;The dimensions have good consistency, and the size error of the same batch steel pipe is ± 0.02mm;

Good material performance, suitable for the follow-up processing of precision machinery;

The surface defects of the product are more easily detected by the naked eye, and the oil pulling process is the guarantee of product quality.

Trace the entire process from rod to finished product;

Provide EN10204 3.1 certificate.

Large-scale production, raw material selection, process optimization, quality control and other factors to ensure quality stability, product consistency, improve product pass rate.

l Standing inventory, rapid delivery, high quality and high price.

Process:

Raw materials →→ (rolling→ degreasing cleaning→ aerobic degreasing→acid cleaning

→ straightening/cutting→ process inspection →→ note: dependants situation) surface coating →coatingdrawing→degreasingcleaning→oxygenated annealing→acid→straightening/cutting→ inspection process→→ → oil lubrication →Oil drawing→ degreasing cleaning→Bright annealing(precision pull can be completed by multiple cycles→ straightening/cutting→ passivation→ vortex detection→ appearance inspection→ pure water cleaning→ ultra-pure water cleaning→ drying→ finished inspection→ cleanroom packaging→ finished product into storage→packaging & transport.

What to detect:

Material composition analysis.

The performance test of the force.

Hardness detection.

Dimension check.

Roughness detection.

Appearance inspection (inner wall, outer wall)

Vortex detection (non-destructive detection)

PMI detection before shipping.

Packing inspection.