Integrated structural/container/pipe/electrical equipment/instrument resources to provide a complete set of services.

Special Performance: Land Drilling Backyard Equipment Module (Inverter, Tank, Water Tank, Workroom, Generator Room, Cable Bridge, Mud Tank, Garbage Station, etc.

2.1 Design services.

Company in order to serve the project and product development, has a professional design team, to provide customers with drawing design services. If the customer provides drawings, we will further decompose the design to facilitate the production process and improve productivity.

Design software: AutoCAD, Solidworks.

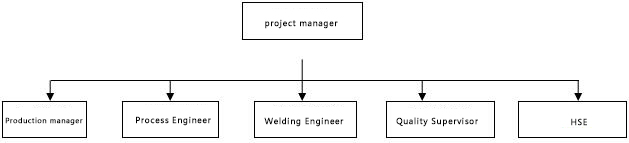

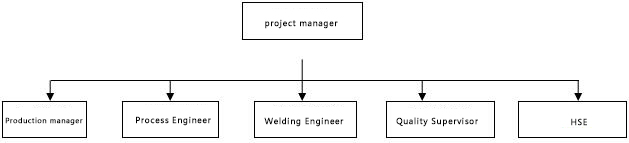

2.2 Project management.

We have a professional project management team, to ensure the smooth progress of the project in the design, procurement, prefabrised construction, installation and commissioning and other aspects of the project, around the "safety, quality, duration, cost control" objectives, integrated management, time management, cost management, quality management, human resources management, communication management, risk management, procurement management and other integrated work.

2.3 Materials available.

Stainless steel.

Aluminum alloy.

Carbon steel.

Forgings, tubes, profiles, pipes, rods are provided, but are not limited to these materials.

2.4 Elbow processing.

Cold bend: minimum 2x bending radius, steel pipe maximum machining caliber 6 inches (168.3mm)

Heating elbow: minimum 1.5x bending radius, steel pipe maximum machining caliber 24 inches (609.9mm)

The hydraulic tube system is flushed with hot oil.

Reference standard: ISO 4021, NAS 1638.

Maximum flushing level: NAS Level 5.

2.7 Hydrostation test.

Reference standard: ASME B31.3.

Maximum test pressure: 300Mpa.

2.8 Lossless detection.

Detection standards:

ASME B31.3 Process Piping.

AWS D1.1 Structural Welding Cod.

ASME V BPV CODE.

ASME VIII BPV CODE.

Detection items: visual inspection VT, penetration detection PT, magnetic powder detection MT, ultrasonic detection UT, ray detection RT.

2.9 Coating.

Surface preparation.

Check the cleanliness and roughness of the steel surface before painting with the naked eye. Steel surfaces must be clean and dry, free of dust, scale, grease, oxidizing skin, rust or other contaminants. The inspectors compare the surface cleanliness of the steel surface with the coating plan in accordance with the relevant standards.

For steel that does not meet the surface preparation, the contractor shall bear the cost of refusing to paint or cleaning again.

Visual inspection must be completed within 4 hours of surface preparation.

b) Visual inspection.

After painting is completed, the painted surface is required to carry out a visual inspection of the final coating defects, detection of flow, bulging, wrinkle, cracking, foaming, shrinking holes, abrasives or foreign substances impregnated, peeling, oxidation or corrosion, pores and other phenomena. The coating must remove all foreign substances to avoid other defects such as bubbles, hanging, leakage, etc.

c) Adhesion detection.

The customer may request a pull test. The absolute minimum value of the experimental results is 5MPa.

d) Dry film thickness detection.

Measured at 5 points per 10 square meters, the average thickness cannot be lower than the specified thickness of each layer of dry film. A single measuring point must not be less than 80% of the specified film thickness, up to 2 times the specified film thickness or the coating manufacturer's coating system data sheet requirements.

e) Detection records.

ll inspection procedures must be fully documented, including the location of the inspection part, the detection device, the detection time, the inspector and the problems it finds.

2.10 Hot-soaked zinc.

ASTM A123 Zinc Hot-Dip Galvanized Coatings On Iron and Steel Products.